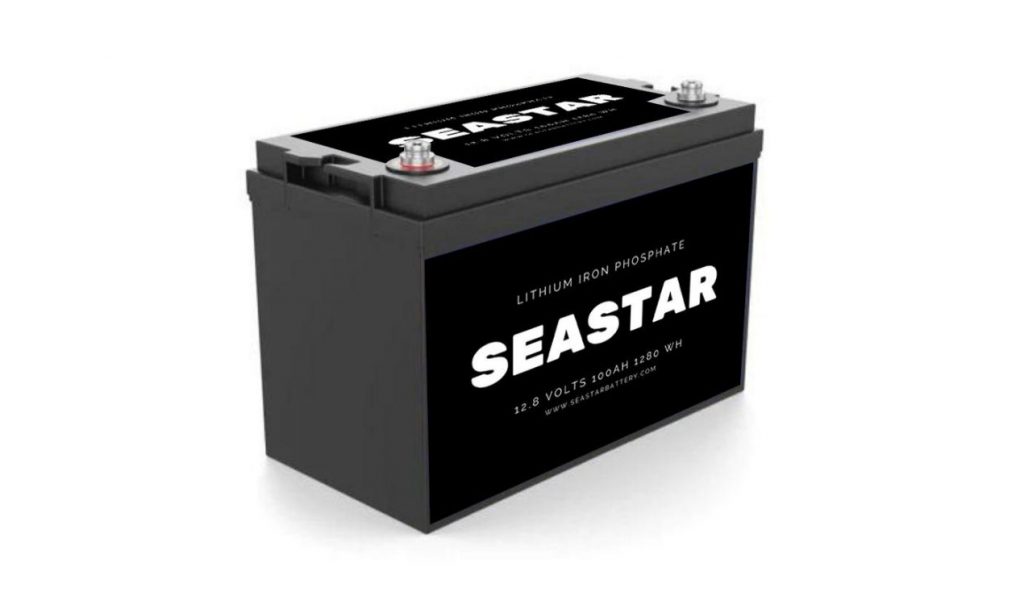

Seastar Battery Custom Solutions: Meeting Specific Customer Needs

As a leading lithium battery manufacturer in China, Seastar Battery not only offers high-quality standard battery products but also provides tailored solutions to meet the unique requirements of global customers.

Our flexible production capabilities allow us to customize designs based on specific customer needs.

Capacity Customization

Seastar Battery offers lithium battery solutions with customizable capacities based on the customer’s application.

Whether a higher capacity is needed for extended battery life or a smaller capacity for lightweight devices, our engineering team can design the most suitable battery system to ensure optimal performance and longevity.

Size and Shape Design

Each project has unique size requirements. Seastar Battery can create custom-sized and shaped batteries to fit the physical constraints and design needs of the customer’s equipment.

We ensure the battery integrates seamlessly into the product, whether for compact devices or large industrial applications.

Appearance Customization

To better match customers’ products, Seastar Battery offers custom design services for the battery’s appearance.

Customers can select different exterior designs, colors, and packaging options that align with their brand and product needs, ensuring the battery not only functions well but also complements the product’s aesthetic.

Special Application Requirements

Seastar Battery also provides specially designed battery solutions for unique applications.

Whether the project demands stability in high-temperature environments or specific voltage requirements, our engineering team can develop specialized battery technology to meet the stringent demands of particular use cases.

Conclusion

Seastar Battery’s customized services allow global customers to receive lithium battery solutions that are perfectly tailored to their specific product requirements.

Whether it’s capacity, size, appearance, or special applications, we offer comprehensive customization support to help customers gain a competitive edge in the market.

Seastar Battery Custom Solutions: Meeting Specific Customer Needs Read More »